|

This

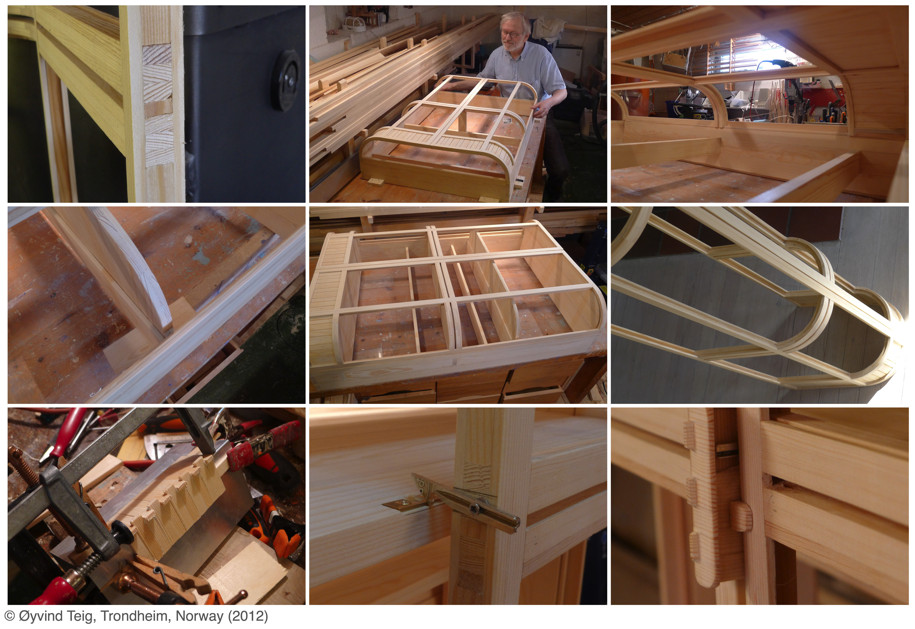

cabinet had two main challenges. The first was to find a glassmaster

(is this the word?) that could make curved glass for me. The second

challenge was to design the doors so that the force from the glass

around the 90 degree corners would not cause any apparent sagging in

open position - and I had a goal to make the whole structure slim. |

|

|

||

| I found a solution to both: 1.

A local glassmaster had an electrical heat oven and also a 180 degrees

half steel tube with diameter 19.7 cm. The first year he tried to place

the glass on the tube, switch the heating on, wait some time up to some

temperature, switch off, wait some time and see what appeared. There

was no window in his oven. But he was not satisfied. So I talked to the

glass shop

at the university here. Sure, they could cut a glass tube, but the

quote was some five times what the glassmaster had quoted. I tried to

negotiate with the humble receiver of the cabinet, but "no, you have

promised curved corners". There was no short cut. A year after I went

to the local glassmaster again and showed him the frames I had made a

year before (pictures 1 and 2 below). I said that I had rather great

margins and tolerance (since the cutting had not been done yet), and

that I could accept the fact that the glass would become somewhat

"white" and loose some of its transparency. I said it would be charming

(and I was true). A week after the 4 glasses were finished, two lower

and two upper 90 degree glasses.

|

||

|

||

|

2. The second challenge

was to design the doors. As usual I started to make the doors with cross lap joint.

But I soon took a break to think it over, since I saw that the sagging

force lines caused by the 90 degree corner would be worsened by the

non-symmetry of a cross lap joint. I wanted the doors to feel stiff as

an airplane wing. Eureka! I could just collapse an airplane box wing

and use equal lists on the vertical parts of the doors, one list on the

inside and one on the outside (picture 1 below). Perhaps this could

be called a "sandwich" construction? The spruce lists are 4x20 mm

(glued from two 4x10mm) in the front and 4x10 mm inside (picture 9

above). Spruce is the wood type used all over. The frames without the

bottom

vertical panel weigh 600 gram each but still feel quite stiff.

|

||

|

||

|

As mentioned I had designed and

glued the "bandy

sticks"

a year before the curved glasses appeared. I used three layers of

overlapping wood pieces, see picture 1 (second frame up from here). In

the

picture you see layer one and two, and layer three is equal to the

first. These also became very sturdy. When the glass arrived I decided

to make no special adjustments per curved glass as they were more equal

than I could imagine. But there are differences which may be seen, but

most of the "free air" is on the inside. I bought a small band saw,

used it, and wondered why I hadn't bought it before.

I used a router

to

cut the place for the curved glass. See picture 6 (second frame up from

here). I used two routing screws to keep distance correct from the

outside. In picture 5 you see how I sanded the bandy sticks precisely

equal. In pictures 7-9 you see how I made the cross lap joints to make

the bandy sticks fit inside the sandwiched construction.

Now let's look at the pictures

in the above frame. The first picture is already described, but I’ll

draw some

design matters here. To make the cabinet look heaviest at the bottom I

added a wooden panel field. I always make lists for these panels of

unequal width, and try to place them as randomly as possible. This was

also done for the back. This way I believe that such a stringent and

clean design is softened a little. Then some way up (the flat glasses

have different heights, the shortest is the lower) is the connection

between the lower and upper glass. I made this of double bandy sticks,

with air between. This gap comes on the middle of a shelf, good for the

tap which the door is pushed into, to lock it from sagging when in

locked

position.

Picture 3 shows how the two

bottom, one center and the top shelf have been built into the sides.

This makes the box very solid. It's a design I also used on another

cabinet, see here.

I made one loose shelf,

veneered from crossing lists, also in three layers. It may be

positioned

at two heights. The bottom layer is not taken all the way to the front,

this makes the shelf look lighter. The two front layers make up for 12

mm. The center picture shows the shelves, also some small shelves.

Picture 6 is just an

arrangement of a cabinet I could possibly make in the future, with the

same kind of doors.

The lower picture

row (above)

plus the first picture (below) show the locking mechanism. It is

screwed in position with brass screws so the lock box may be removed

for service. I used an old key to make the lock. The door click-closes

easily by pressing it in. It opens by putting the fingers behind the

handle and pushing the key down, and at the same time push the door a

little. The doors do not touch the shelves, but there is a small piece

of

wood on the top and bottom to make this pressing a little soft (a gap

in the center just behind the handle). Even if

the door construction is stiff, it easily is pushed half a millimeter

in. See this piece and gap on the topmost leftmost picture of the grey

top with signature and copyright statement. The lock locks both doors.

|

||

|

||

|

The pictures above show the

painting process in picture 3. As usual I paint with oil paint and then

dry off wet paint with a cloth. This time it was much more difficult,

since the owner wanted two colours. I used a million cloths! Colours

are greyish Jotun "S 1010-R80B" and blue-violet "S 3060 R70B". Pictures

4 and 5 are without glass and show our ceramic SanGimignano1300 model and my two

SBB

Ae 3/6 II Märklin locomotive models. Both certainly out of place -

both adding beauty.

Then there is the

transportation phase in the back of the car. Now it hangs on the wall,

much more filled than the initial filling. The last picture shows a

roof door stopper I needed to make to protect the cabinet. It's made of

a

laminated glued shelf bracket and a piece of rubber, plus a pad of felt

on the door.

I have not shown the details of

the bottom and back panels. There is about 3 mm of gap between each

list.

Also, the two holes for mounting are not seen, inside the cabinet. They

are taken through two layers of

crossing wood, firmly glued inside a tapping so the lists can't move.

Also, the flat glasses are lifted up into a 6 mm groove and let fall

down into a 3 mm groove. And some drops of silicon. This is almost like

in this

cabinet, but not on the sides: I use separate lists on the sides here.

The hinges are brass, but I had to cut the top ones to half length

because the doors had too little material there. One of the downsides

of making prototypes only! But it became more than sturdy enough.

Between the bottom and the first shelf (behind the panel) I made a

vertical structure (up-down and from front top to bottom rear, like a

bridge) that would stiffen the bottom part, so that it may stand on a

table during mounting without wiggling or breaking the bottom. There is

no picture of this.

The dimensions are 70.4 x 98.4

x 23.4 (WxHxD) cm. Flat glass dimensions are 21.1 cm width, upper

height is 49.6 and lower 32.6 cm of 3 mm thickness. Curved glass has

19.7 cm inner diameter (=outer diameter of steel tube) and upper height

50 and lower 33 cm. Upper thickness 3 and lower 4 mm I noticed. The

complete cabinet weights 16 kg.

If you liked this cabinet, the follow-up is Wall cabinet with 45 deg corners. |

..

|

|

|

Robert

Revdal at Glassmaker'n

in Trondheim made the curved glass (this is not an advertisment!)

Glassmaker'n has cut all glass for me over the years. |

||

| |

©2012

- Original design and woodcraft by Øyvind Teig, Trondheim, Norway |

|

Search

words in Norwegian: Hjemmesnekret vitrineskap med runde hjørner av

glass, glasshjørner, låskasse, panelt bakplate. Hengeskap. Om du likte det, se

neste skap der |